OILFOX

Biodigestores

¿Qué es un Biodigestor?

Un digestor de desechos químicos o biodigestor es, en su forma más simple, un contenedor cerrado, hermético e impermeable (llamado reactor), dentro del cual se deposita el material orgánico a fermentar (excrementos de animales y humanos, desechos vegetales-no se incluyen cítricos ya que acidifican-, etc) en determinada dilución de agua para que a través de la fermentación anaerobia se produzca gas metano y fertilizantes orgánicos ricos en nitrógeno, fósforo y potasio, y además, se disminuya el potencial contaminante de los excrementos.

El biodigestor es un sistema sencillo de implementar con materiales económicos y se está introduciendo en comunidades rurales aisladas y de países subdesarrollados para obtener el doble beneficio de conseguir solventar la problemática energética-ambiental, así como realizar un adecuado manejo de los residuos tanto humanos como animales.

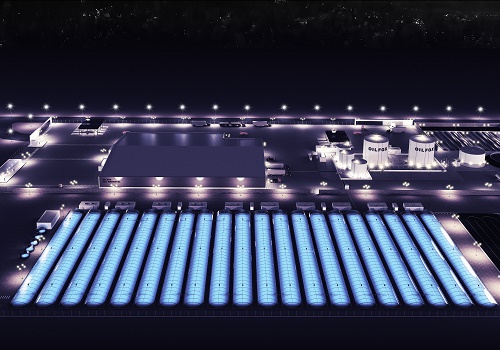

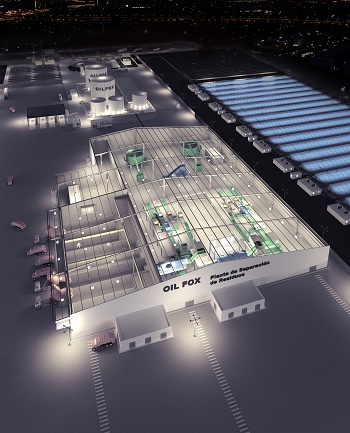

Oil Fox cuenta con tecnología de primer nivel para el desarrollo de diversos tipos y tamaños de Biodigestores para abastecer diferentes demandas en relación a los residuos con los que se cuenta.

Magnitudes de producción:

Una (1) Tonelada diaria de residuos orgánicos en promedio genera cincuenta (50) m3 de biogás por día. A su vez un metro cubico (1m3) de biogás genera uno punto cuarenta y cinco kilowatts/hora (1,45 kw/h).

En una ciudad tipo en promedio, cada habitante genera uno punto uno kilogramo de basura (1,1kg) diarios. De este el sesenta por ciento (60%) es orgánico. Es decir (como para tener un parámetro), una ciudad de cien mil habitantes (100.000 habitantes) genera aproximadamente sesenta y seis mil kg (66.000 kg) de basura orgánica diaria o sesenta y seis toneladas (66 TN).

Según los datos expuestos se podrían producir tres mil trescientos metros cúbicos de biogás (3.300 m3) y por lo tanto cuatro mil setecientos ochenta y cinco kilowatts/h (4.785 kw/h o 4,78 Mw/h).