The Biodiesel is a fuel produced by renewable raw materials, such as vegetable oils, that can be used on diesel engines. It’s a fuel to replace the petroleum diesel, produced by renewable natural resources such as vegetable oil, animal fat and recycle Edible oils. Examples of raw materials used to make biodiesel are: soy oil, canola oil, cotton oil, sunflower oil, corn oil, sebum/tallow, bacon, algae and yellow fat.

Economic feasibility determination for the development of biodiesel

EXECUTIVE SUMMARY – INTRODUCTION

The development of a program which objectives are basis on the future convenience to count with fuel coming of renewable resources, and taking into account the growing worldwide demand referring to the environmental protection, emphasizing between others in the reduction of the emission to the atmosphere of contaminant gases, they are Valid arguments and of indisputable solidity as to plan and develop actions tending to contemplate this demand.

On the other hand, as biodiesel is a byproduct coming from the processing (among others) of the soy, the possible future demand of its utilization will stablish the creation of a new market with a huge growing potential, giving an alternative exit to the producers of the primary production, who may be benefit with an additional demand strengthening of low prices which the actual markets offers to the commodities.

ADVANTAGES

– Competitive against other technologies which reduce the contamination.

– Complement all the new diesel technologies for the reduction of contaminant gases.

– Similar performance to the diesel fuel

– It does not need a new infraestructura or training.

– It’s not necessary to change or convert engines.

– it does not alter the maintenance equipment.

– It does not alter the time of fuel recharge.

– It does not alter the Torque

– it does not alter the consumption.

– It improves notably the lubrication in the circuit and in the injection bomb.

– It improves the wintry functioning conditions.

– It improves the anti-explosion and fire conditions.

– The mix can be done at the chargin moment or previously.

– The mix is stable and it doesn’t separate into phases.

– They are not in the same tank as the gasoil ones, they are not toxic and it does not make explosive mix with the air.

ENVIRONMENTAL IMPACT

– Reduces, in the scapes, the fraction of carbon into particles.

– Reduces the quantity of carbón monoxide

– Reduces the quantity of Unburned hydrocarbons

– Reduces the emission of Polycyclic aromatic hydrocarbons

– Reduces the quantity of Sulfur oxides

– It offers a net benefit of 45 to 71% less of CO2 emissions to the diesel engines, in comparison to the gasoline.

-The Oilseeds culture absorbs the CO2 while they grow, so in the balance they is no Increase in emissions.

ECONOMIC IMPACT

– Emergence of a new market

– Value added to the base material (oil seeds)

– Plant and equipment investments

– More quantity of employment

– More tax base for plant operations and utility taxes.

TOXIC SHOCK REDUCTION

– Sulfur emulsions are reduced by 20%.

– The visible starter smoke is reduced by 30%.

– Smell is Significantly reduced

– The irritability of eyes and skin is deleted.

JUSTIFICATION

The biodiesel industry has a promissory future, it is obtained by vegetable oils with a simple process of refinement. One of the main commodities required is the soy, biggest culture in Argentina, produced by thousands of producers in eight provinces.

COMPATIBILITY

There is a significant amount of relative information to the compatibility of biodiesel materials and their mixtures. In general terms, biodiesel is not compatible with natural rubber elastomers or copper-containing metals.

IMPACTS ON THE DIESEL ENGINE

In any diesel engine, a small quantity of fuel goes between the piston rings to the engine oil. Typically, a Greater dilution of the oil in diesel engines with direct injection is experimented than in engines with indirect injection. The dilution of the oil in engines is important from two points of view.

First, the diesel fuel is considerably lighter than the oil and has less lubricant power, that’s why it reduces the oil’s ability to lubricate the engine. Second, after a time period, the antioxidants in the engine oil are used by the fuel that the filter and the same begins to polymerize, causing thickening. Obviously, the excessive thickening of the oil difficult the free movement of such through the engine, resulting in a poor lubrication and a higher wear of the engine.

Duration of an Engine with Diesel

The duration of engines that use biodiesel have been specifically studied in Brazil by Volkswagen, using pure biodiesel and mixtures. In USA,more than 30000000 of km. have been made without any kind of problem during this last four years. All the information indicates that the durability of the engines is comparable when biodiesel or diesel wich derivative from petroleum is used.

Fluency at low temperature

It has been made various experiences with biodiesel and many mixtures at low temperatura climates. Generally, with B-20 or less, the mixture will start freezing between 1 and 3 centigrades above than the petroleum diesel. Most of the biodiesel properties (emissions, power, etc.) are independent of the oil or grease used as raw material, but the low temperature fluidity properties are affected by the raw material used, in the case of pure biodiesel and in smaller measure in their mixtures. The pure biodiesel manufactured From soybean oil has a Cloud Point of -5ºC and a fluency point of -8ºC, meanwhile the biodiesel of Palm oil has a “Cloud Point” of 15/30ºC. The mechanisms to minimize the problems on very cold zones are basically the sames as for the diesel:

1. Mix with Kerosen

2. Use a fluency improver

3. Use a fuel filter with heater

4. Keep the vehicles under roof.

Most of the diesel engines recycle a Substantive quantity of fuel through the engine returning to the fuel tank and this is used to heat the fuel in the tank. This eliminates the fluency problems at the cold time once the engine has started.

Biodiesel Attributes

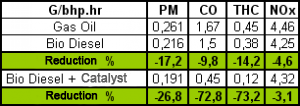

EMISSIONS

Lots of investigations have been done about the emissions of many bidoesel mixtures with conventional diesel. The data coming from the engines test in USA, the tests made by Volkswagen in Brazil, as others tests made in Europe has provided the necessary information to understand the type of emissions when biodiesel and mixtures are being used at the same time, without any necessity of repeat the really expensive tests made in engines.