|

|

Biodiesel

Biodiesel is a biofuel for diesel engines derived from vegetable oils. The biodiesel chemistry includes methyl, ethyl and alkyl esters. It has also been registered as a fuel additive in the Environmental Protection Agency (US EPA).

Determining the economic feasibility of biodiesel development

EXECUTIVE SUMMARY - INTRODUCTION

Taking into account the growing environmental concerns worldwide, a renewable fuel programme focused on fewer gas emissions is essential.

Since biodiesel is derived from soybean oil, our project carries significant prospects for local commodity producers, who will obtain additional benefits from increasing demand and commodity prices.

Advantages

- Biodiesel is a competitive fuel reducing pollution.

- It supplements petrodiesel technologies to ensure fewer gas emissions.

- Performance similar to petrodiesel´s.

- No additional infrastructure or training.

- Unchanged diesel engines.

- Unchanged maintenance services.

- Unchanged refuelling time.

- Unchanged torque.

- Unchanged fuel requirements.

- Improved performance in winter.

- Improved anti-explosion/fire performance.

- It may be blended prior/upon refuelling.

- Stable blend.

- Soybean esters are stored in petrodiesel tanks since they are not toxic or hazardous.

Environmental Impact

- Reduced carbon particles in exhaust gases.

- Fewer carbon monoxide emissions.

- Fewer hydrocarbon emissions.

- Reduced polycyclic aromatic hydrocarbon emissions.

- Reduced sulphur oxide emissions.

- 45-71% fewer CO2 emissions relative to gasoline.

- Fewer emissions as CO2 is required for oilseed growth.

Economic Impact

- New market.

- Value added to oilseeds.

- Additional infrastructure investments.

- Increased employment levels.

- Increased tax revenues from project operations and profits.

Fewer toxic emissions

1-Sulphur emissions reduced by 20%.

2-Start-up fumes reduced by 30 %.

3-Reduced smell.

4-No skin or eye irritation.

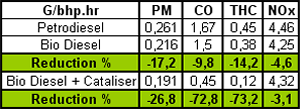

PM= suspended particles

CO= carbon dioxide

THC= hydrocarbon

NOx= nitrogen oxide

Based on 10 million km test results.

Justification

The future outlook for the biodiesel industry looks promising. Biodiesel is obtained from vegetable oil through a simple refining process. Feedstock include soybean -currently the largest crop grown in Argentina by over 100,000 agribusiness from 8 different provinces.

Compilant components

Biodiesel components and blends are generally compliant. Biodiesel is not compatible with natural rubber elastomers or copper metals.

Impact on diesel engines

In diesel engines, some fuel seeps through the piston rings into the oil container. Typically oil dilutes in direct injection engines. Diesel fuel is much lighter and has less lubricant capacity than oil. As a result of polymerisation, oil thickens with reduced lubrication capacity and increased engine wear.

Biodiesel engine performance

The performance of biodiesel engines has been specifically tested by VW in Brazil. No impact on vehicles subject to a 30 million km trial for the last four years has been identified by US assayers.

Other durability tests

Trials have been recently completed by Cummins engineers researching at the University of Missouri on a direct injection 5.9 Cummins biodiesel engine along 160000 km, with highly successful results. They found out that engine wear is probably lower with biodiesel than with conventional petrodiesel.

Biodiesel fluidness at low temperature

Biodiesel has been trialled in low-temperature areas. Most < B20 fuels will freeze 1 to 3 centigrades above petrodiesel. Whilst the cloud point of pure soybean biodiesel is -5°C and its fluidity point is -8°C, the cloud point of palm-oil biodiesel is 15-30°C.

Follow the same precautions as those applicable to petrodiesel in cold weather, namely:

1 - Mix with kerosene

2 - Use a hot fuel filter

3 - Park vehicles indoors

Fuel is recycled and heated in the tank of most diesel engines to ensure fluidity in cold weather.

Biodiesel properties

Emissions

The chemistry of biodiesel emissions, when mixed with conventional diesel fuel was extensively researched. Data was gathered from the engine tests in the USA, the tests made by Volkswagen in Brazil, as well as other tests in Europe. Such information was used to ascertain the chemistry of biodiesel emissions in order to avoid further engine tests.

|

|

|

In the past, cientific, technological, commercial and industrial development were not based in what we know now as "social responsability".

In eastearn countries like China and japan, they develop processes and research based on community well fare and humanity.

Oil Fox was born thinking on the enviroment; It was the main partner's objective because a healthy enviroment is better for their employees, their families, socety, etc.

With that aim in mind, executives decided to establish new parmeters that will be taken into account on the execution of the Biodiesel Project.

These new parmeters respond and articulate with the corporate objectives wich are:

1) Oil Fox develops technology to help the enviroment, protect biodiversity, create sustainable develop without wasting natural serources, while using renewable energies.

2) Families working on the project and the communities affected indirectly will receive special attention. In particular, those native populations living in the country. It is well known that destruction of the enviroment has negative effects on these communities in particular.

3) Before the controversial between food and Energy started, Oil Fox was alraedy working in 1999 on non edible oil seeds as an alternative of soybean. In Salta, we planted Ricino, avoiding enviroment destruction associated with soybean cultivations.

4) Oil Fox is creating a network with diferent countries in Latin America to transfer technology to anyone who needs it . Some of the countries goverment, corporations, or social organizations are from Paraguay , Bolivia , Chile , Peru , Ecuador , Republic Dominicana, Mexico , Honduras y Panama.

5) As a ground breaking project , Oil Fox is making lots of effort and transacts to create a farm school to children from all the country who are interested in learning outdoor activities. We will craete a foundation for boy scouts.

6) Thanks to Oil Fox developments, we are creating a high protein algae based food complementary, much better than soybean . It is estimated thas these algae has 70% of protein content, much more than any oilseed. This by - product will contribute to supply world- wide food needs.

|

|

|

Biodiesel properties

Biodiesel was introduced to Mercosur[1] members in December 1997. Public-private trials were carried out to demonstrate biodiesel performance in local transportation services, with the support of the following agencies:

- The National Department of Agribusiness, Fishing and Food.

- The Buenos Aires Minister of Agrarian Affairs.

- The Santa Fe Minister of Agribusiness, Industry & Trade.

- National Transport Department.

- The Buenos Aires Department of Environment and Urban Planning.

- INTA´s Rural Economics and Sociology Division.

|

Being ahead in the research and development of new technologies and strategic plans, our company is focused on the following:

1 - The installation of the first B100 station in Latin America. We are currently awaiting the resolution from the local authorities to proceed to project implementation. Resources are available for the development of a biodiesel processing facility out of used oil. Agreements are now in place for the supply of raw materials, lab assaying and biodiesel sale. Used oil will be collected through an agreement with several NGOs.

2 - An agreement has been reached with the Argentine Air Force to assess biodiesel tests results when used as aircraft fuel.

3 - The 2006 PAN AMERICAN trip along 27,000 km, from Alaska to Ushuaia was undertaken, with very good results -it was a Guinness record. This clearly shows the outstanding performance of pure biodiesel. -See at acknowledgment-

4 - Agreements have been reached with local universities for biodiesel research and development in compliance with international standards –including ASTM and EN 14214.

5 - Agreements have been reached with local universities for biodiesel research and development using biological catalytic converters.

6 - Based upon the experience gained during all these years (From 1997 to date), Oil Fox S.A. has decided to launch into the design, construction and sale of turn - Key Biodiesel production plants of latest generation technology, with capacities ranging from 1000 to 20000 tons per month.

7 - An agreement has been executed with the School of Engineering and with the School of Pharmacy and Biochemistry of the University of Buenos Aires to exchange technologies, research, development, ect. related to biodiesel, as well as to improve student training, organise internships, improve technology, etc.

8 - A strategic alliance agreement hast been executed with Establecimientos Metalúrgicos Universales S.A(EMU) so that the "turnkey plant contruction" business unit is organised with the highest experience, quality and commitment the market deserves (see business unit records).

9 - An agreement has been executed with Universidad Nacional del Litoral, the School of chemical engineering, instituto INCAPE, to train our technical employees and to test the new technologies used by Oil Fox to produce Biodiesel in order to comply with the existing standards.(Iram, Astm , Din, etc.)

10 - Essays are being done for extract oil from freswater and brackish water algae. Preliminary results shows higher productivity and oil extraction to produce Biodiesel, Bioethanol and proteins for animal and human consumption.

11 - Last january 23rd. took place in Madrid , organized by Global Energy, a conference about "Biodiesel based in algae". Oil Fox was invited to exposed the project with other groups from USA , Latin America and Europe.

12 - Oil Fox participated also of the exposition "Genera 08". The conference took place in Madrid (España) and Renewable Energy in general were discussed.

13 - Oil Fox gave a conference about Biodiesel based in Algae in the University of Salamanca. There, a cooperation agreement started (including research and financial support) to develop the proyect in Spain.

14 - This year, past october during the 30 and 31st, in the University of Alicante, Spain, a conference about biodiesiel based in algae demonstrate the level and advance of our project compared to others. The participants were from Venezuela, Mexico, USA, Holland, Ireland, Spain and others.

And we keep working...

OIL FOX S.A......

ALWAYS A STEP AHEAD!!

|

Reasons why OilFox has the best technologies for algae-based Biodiesel production

1 - Because we do an efficient use of resources. We produce biogas from anaerobically digested organic matter which then is burnt to generate electricity (for paddle wheels, light, harvesting and drying process).

2 - We use the anaerobic digestion effluent as a source of nutrients for the algae to grow.

3 - As with all photosynthetic organisms, algae use CO2 as a carbon source. Natural dissolution of CO2 from air into the water is not enough so we will bubble flue gas emitted from a thermal power station into our algae cultures to improve productivity and to reduce CO2 emission since this gas is considered to be one of the main causes of the global warming problem.

4 - We water the surrounding park with rain water collected with special devices.

5 - To build the charge and discharge area we used waste material from a steel-making plant next to our plant.

6 - We do not use water to wash and purification of biodiesel. We do not use water at all. Instead of that, we use ion exchange resins for the pretratement of the oil and post-treatment of biodiesel.

7 - Once the ion Exchange resins cannot be used anymore, we spread it in the charge and discharge area, were the waste steel-making material is. When the mixture is heated, a carpet similar to the asphalt but more resistant is created without using non renewable resources.

8 - At first we used metal structure to build our greenhouses but as they were ruined by the algae growth medium, we decided to use recycled plastic . It is not only environmental friendly but also more resistant.

9 - To transesterificate the fatty acids with an alcohol and produce biodiesel, a catalyze is prepared mixing sodium hydroxide with methanol. To avoid human manipulation of the solvents, we prefer to use sodium metilate already prepared to minimize risks.

10 - After harvesting the algae, the water from the culture medium is potable for human comsumption.

11 - After oil extraction from the algae sludge, the remaining biomass can be used for animal o human consumption after bacteriological analisis.

12 - To grow algae at night, we use artificial Light (LED) which have high efficiency and low cost and consumption of energy.

13 - The biodiesel plant is totally automatic, to avoid human contact with potentially dangerous solvents like methanol. In the production area, a robot with sensors is able to gather information of gases, temperature, valves and pumps on real-time.

14 - Because of their particular features our greenhouses could be considered as photobiorreactors due to our special technology developed (registered). It's high productivity is similar to mixotrophic photobiorreactors. These include steering paddles wheels, harvesting and nutrient replacement devices and light dispersion giving priority to the most efficient and low cost technologies.

|

1. Offices

Our offices are located in the historic building "The Barolo Palace" in the city of Buenos Aires

2. Conferences

Conference and visit to the agro cience centre of the salamanca university

Conference at alicante university(spain). By jorge kaloustian about biodiesel from algae.

4. Expedition

Members of the 2006 Pan American Expedition (Alaska-Usuhia) who used biodiesel fuel provided by Oil Fox S.A

5. Biodiesel Samples

7. Several

|

Interview about OIL FOX S.A.

Interview about OIL FOX S.A. Biofuels plant built

Biofuels plant built

Biofuels plant built

Biofuels plant built |

|

Aalgae

Algae are part of our daily lives. Although it is very difficult to survive without them, these and their various derivatives, our lives would be very different without missing. Without realizing it, every time we are in contact with some seaweed derivative. They are part of our life in food, drugs and even in painting and in our clothes. Algae are a source of many useful products.

Characteristics of the algae

GENERAL COMPOSITION:

| Proteins | 55-70 % |

Minerals | 7-13 % |

| Carbohydrates | 15-25 % |

Moisture | 3-7 % |

| Lipids (*) | 4-47 % |

Fibers | 4-7 % |

(*) Depending on the type of algae

CONTENT IN 10 GRAMS

Biogas

Example of Generating Waste Biogas with Algae.

Photos of Algae

4. Automation

5. CO2